Card Features

Metal Card Shape

Our metal business cards can be made into any size you require. The standard metal card sizes are 85mm x 54mm (3.3” x 2.2”) - the size of a credit card.

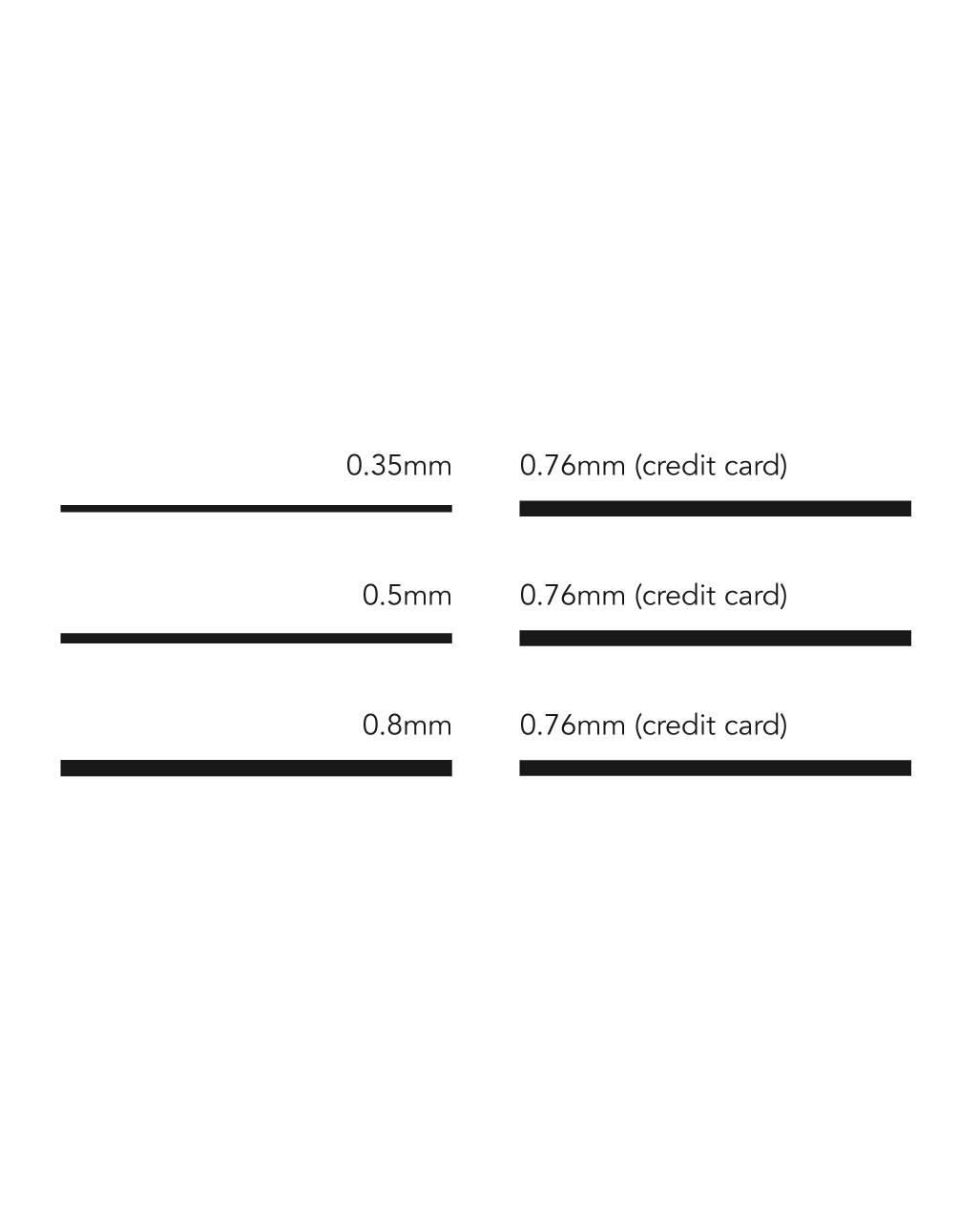

Metal Card Thickness

0.35mm

It is distinctive and unique, yet thin and light with some flexibility. A great choice for light business cards.

0.5mm (recommended)

It is our most popular metal card thickness. Perfect mix between thin- and heaviness, giving a more premium feel. A great choice for business and membership cards.

0.8mm

It is the thickness of a credit card. Thicker cards are often perceived as premium and luxury. A great choice for VIP cards.

Download Template & Specs

You're welcome to download our blank template and specs below for preparing your print files. Please be aware that while client vector files are essential for generating a printing proof, using these templates does not substitute for the proofing process. After you place an order, our design team will produce an official proof to confirm that everything meets our precise specifications. The final proof we provide must receive client approval before we can begin production.

Finishing Options

Discover the high quality and eye-catching design features you can utilise for your custom metal business cards and metal products:

Etching

FREE FINISH

Chemical etching is the technique used to precision-etch custom artwork into the stainless steel card surface. The process uses acid to etch away unwanted metal, while a photographically prepared mask (Phototool) is used to protect the metal areas that are to remain after the etching process. Regular etching will show a 10% debossed finish, while deep etching achieves 50% depth.

Cut Out

FREE FINISH

The chemical etching process is used to etch into the same position on the front and back of the card surface. When the two areas come into contact, the piece will fall out creating a unique and visually stimulating cut through effect.

Etch & Fill Spot Colour

FREE FINISH

After etching, the recessed areas are filled with a specific spot colour, enhancing the design's visibility and adding a vibrant, durable finish.

Spot Colour Printing

FREE FINISH

The screen printing process is used to print solid spot coloured inks onto the stainless steel card surface (we will match to your specified spot colours). Each individual card is carefully screen printed by hand.

Laser Engraving

To achieve stainless steel highlights, we laser engrave (remove) the top layer to expose the stainless steel colour underneath.

* Laser engraving is extremely accurate making this process perfect for small logos, design elements and text. Unlike chemical etching, laser engraving only removes a thin layer of the stainless steel material and does not create a deep deboss.

Full Colour Printing

Complex colourful graphics, photos, and logos may require more than two colours for accurate reproduction, ensuring vibrant and detailed designs.

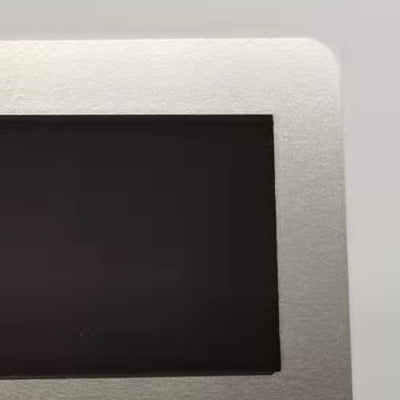

NFC Chip

NFC chip cards, used as business or membership cards, offer seamless, contactless data transfer to smartphones for enhanced convenience and security.

The NFC chip (Ntag215) will be partially embedded within a mold created through deep etching and covered with a custom printed sticker. You can choose between square and round NFC chips (25x25mm). Encoding is included.

Barcode

Barcodes on membership and gift cards streamline check-ins and track usage efficiently. The code can be printed or laser engraved.

Please let us know the type of code required e.g. EAN-13, Code 39, Code 128 etc.

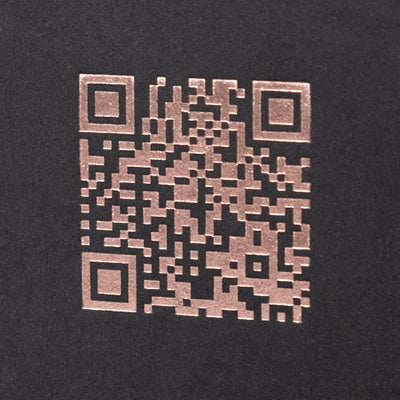

QR Code

QR codes on business or membership cards provide quick access to detailed information, enable easy contact sharing, and enhance engagement with digital content.

The code can be printed or laser engraved.

Magnetic Stripe

Magnetic stripes on gift or membership cards securely store encoded data, enabling seamless transactions when swiped through compatible card readers. We offer LoCo and HiCo which come encoded.

Signature Panel

A white signature panel will be printed on the cards, allowing for personalisation or signatures.

Magnetic or Adhesive Backing

Magnetic backing allows for easy placement on metal surfaces.

Adhesive backing provides a convenient way to attach the cards to different flat surfaces.

Need help with your design?

We have a team of professional graphic designers that will create your own custom business card design. Simply add our design service when ordering your cards. Or contact us if you have any questions about our card finishing options.